Research Interests:

Morphology of self-assembling materials of controlled molecular architecture including; Block Copolymers, biopolymers, liquid crystalline polymers, and semicrystalline polymers; Electron microscopy, X-ray and neutron scattering.

Current Research:

My research is focused on understanding how controlled polymer molecular architecture can be used to guide the self assembly and processing behavior of materials in order to create novel and useful structures on a morphological length scale (nanometers to microns). Materials of interest are those in which either nature or the synthetic polymer chemist exercises precise control over molecular weight, monomer sequence, sterioregularity, chain branching, etc A significant fraction of my research effort is focused on the study of proteins and synthetic polypeptides with highly repetitive amino acid sequences that form unusual crystalline and liquid crystalline structures. An important part of this work is an effort to understand the natural process of silk spinning in spiders and silk worms. By understanding how the natural spinning process exploits molecular self-assembly we hope to be able to design effective processing strategies for synthetic silks. Other classes of materials with well defined molecular architecture that we are investigating are block and graft copolymers, synthetic polymer liquid crystals, and models for the polyolefin materials produced by new metallocene catalysts. As a polymer morphologist, I rely heavily on electron microscopy and scattering techniques to determine aspects of materials structure that are then related back to the molecular architectures and the self assembly processes. The following descriptions give some perspective on two of my major research focuses, but my work is not limited to these areas.

Graft and Block Copolymer Molecular Architecture and Self Assembly

The goal of this research is to understand how variations in the molecular architecture of graft copolymers can be manipulated to control the nano-scale structure (morphology) and the ability to form long range order during self-assembly. Self assembling block copolymer materials have important commercial applications as thermoplastic elastomers, and compatibilizers in polymer blends. Recently more advanced applications for these materials are being developed. These include using block copolymers morphologies as templates for the production of nanostructures, in nanoscale lithography, and as selectively permeable membranes in new fuel cell designs. By doping block copolymer morphologies with quantum dots, the long range order and crystallographic symmetry of the block copolymers have been utilized to create materials with unusual electro-optical properties. We have been working with the U.S. Army research laboratory to develop selectively permeable materials based on chemically modified (sulfonated) block copolymers that allow permeation of water vapor but block chemical and biological warfare agents. All of these applications make use of the self assembled, nanoscale separated domain structure of block copolymers. In order to optimize performance one needs to be able to control the size, shape and symmetry, and overall volume fraction of different types of domains independently. This independent control, however, is not possible with conventional linear AB diblock copolymers and ABA triblock copolymers for which the nanophase separated morphology which forms(spheres, cylinders, cubic bicontinuous, or lamella) is tied directly to the relative volume fractions of the two block materials. For instance, if an application demands a material with microphase separated nanometer length scale cylinders in which the component comprising the cylindrical domain makes up over 50 volume percent of the material, linear block copolymers would not be useful. Or suppose one needs an alternating layered structure on a similar length scale in which the layers differ considerably in thickness, i.e. thick layers alternating with thin layers. The lamellar structures formed by linear block copolymers would not suffice in this case since they are formed only when volume fractions are near 50/50.

A way to uncouple block copolymer morphology from its rigid dependence on component volume fractions is to introduce another variable by varying molecule architecture in novel ways. One might suppose that a plurality of new block copolymer molecular structures would introduce a plurality of new variables to be considered in the morphological behavior. However, it is our contention and one of the key premises of our research, that a large number of the possible variations can be represented by a single molecular asymmetry parameter. This parameter contains a factor describing the conformational asymmetry between the two block materials and another factor describing the asymmetry inherent in the molecular architecture (the way in which component blocks are linked together). A central problem of the current research is then to determine the architectural asymmetry part of a generalized asymmetry parameter for any of the various graft copolymer architectures encountered. That problem has been address by our published work on graft copolymers and continues to be the subject of ongoing investigations.

Other ongoing research in block and graft copolymers has focused on the effect of molecular architecture on the degree of long range order in the self assembled morphologies formed. Recent work on crystallizable block copolymers in my group has led to the discovery of crystallographic registry between adjacent domains which are separated from one another by up to 10 nm of flexible amorphous material. TEM and electron diffraction suggests that the communication between crystalline domains which enables crystallographic alignment results from the presence of screw dislocations in the layered block copolymer structure.

Biopolymers

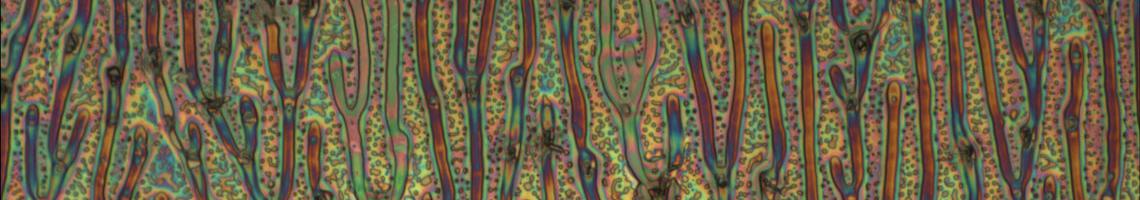

The exceptional mechanical properties of silk fibers and the efficiency of silk spinning in nature have produced an effort to understand the natural silk process as it proceeds from the biosynthesis of the silk protein (fibroin) through the spinning of the fiber. We have been able to observe and image a cholesteric liquid crystalline phase of silk fibroin as it exists within the silk-producing glands of two silk-spinning species, Nephila clavipes (spider) and Bombyx mori (silkworm).1 This observation was accomplished by cryogenically quenching the animals in liquid propane during the spinning process and then analyzing the morphology of the material within the silk gland using TEM, electron diffraction, and atomic force microscopy (AFM). Electron diffraction results also support the picture of the aqueous silk phase existing as a liquid crystal at an intermediate stage of the silk spinning process. This liquid crystallinity aids in the molecular alignment necessary for high performance properties in the final fiber.

In addition to the silk spinning work, I have been investigating the effect of amino acid sequence on crystal structure and on chain conformation at interfaces in fibrous proteins and synthetic polypeptides. The general goal is to better understand how the physical environment and the protein sequence interact to direct crystal structure and properties. TEM and electron diffraction are being utilized to study the effect of interfacial physics (at the air-water interface and various aqueous-organic liquid-liquid interfaces) on protein chain conformation and crystal structure. We have also developed a foaming technique in order to obtain, for characterization, larger samples of interfacially directed crystal structures of silk and other proteins.

The role of the surrounding environment in controlling protein structure and activity is profound. Globular proteins partition in water such that hydrophilic amino acid residues reside in or near aqueous contact while the hydrophobic residues become occluded within the structure and shielded from the water phase. Protein folding typically involves nonrepetitive amino acid sequences and complex three dimensional geometries, and not surprisingly is extremely difficult to understand. In our work, we reduce the complexity of the amino acid sequence by using structurally repetitive fibrous proteins or synthetic polypeptides and we reduce the geometrical complexity by confining self-assembly to an essentially two dimensional interfacial region. Within this simplified context we can gain insight into the interplay between chemical segregation effects and chain sterics by observing the structures (chain conformations) formed as a function of residue sequence and aqueous-organic interface characteristics.

Silk worm (Bombyx mori) silk contains about 60% of the crystallizable repeating sequence (GAGAGS)n. This sequence occurs in crystallizable blocks which are separated by less repetitive sequences incorporating amino acids with bulkier side chains that do not crystallize. Prior investigators have reported two crystalline polymorphs for silk, designated silk I and silk II. Silk II is the common b-sheet crystal found in the silk fibers spun by the silk worm, while silk I is a less well-characterized, metastable crystal structure which may be an important intermediate in the silk spinning process.2,3 My group has recently reported the discovery of a third silk polymorph which forms specifically at the air-water interface and aqueous-organic liquid-liquid interfaces.4,5 The combination of the silk crystallizable sequence and the two-fold helical chain conformation of the silk-II structure places the side chains of both the alanine residues (-CH3), and the serine residues (-CH2OH) on the same side of the b-sheet. This arrangement poses no difficulty in bulk silk fibers but leads to an unfavorable situation if the structure is placed at an air-water or aqueous-organic interface because it fails to separate the hydrophilic serine side chains and the hydrophobic alanine side chains to opposite sides of the interface. Based on electron diffraction of silk crystallites, we have proposed a new crystal structure based on a threefold helical chain conformation which occurs specifically at interfaces. The combination of the six fold amino acid repeating sequence and the three-fold helix allows separation of the hydrophilic and hydrophobic side chains to opposite sides of the interface. This structure, which still resides in the allowable chain extended region of the Ramachandran conformational map, is similar to the three fold helical structure known as polyglycine II and also to the 3.3 fold helix formed by collagen. Our molecular modeling calculations show that, while the three-fold helical silk structure has a somewhat higher steric energy than the stable bulk structure (silk II), the partitioning of alanine and serine residues more than compensates when the structure is placed at an interface.

In a separate biopolymers project we have discovered an unusual twist grain boundary (TGB) liquid crystalline phase in monodisperse poly(g-benyl a,L-glutamate) (PBLG) produced by recombinant DNA techniques.6 Conventional polydisperse PBLG, when it is enantiomerically pure, has been known for many years to form cholesteric phases due to the a-helical secondary structure of the chains. Superposition of the uniformity of chain length in our monodisperse materials upon the helical chain conformation leads to the superposition of smectic-like layering on top of the helical twist of the cholesteric. This results in the unique symmetry of the TGB phase that we were able to identify with TEM, AFM and electron diffraction studies. On going work in this area is focusing on the effect of molecular weight and chemical modification on the characteristics of these twisted liquid crystalline structures.