Welcome to the Watkins Research Group's home page. We are a collection of polymer scientists, chemical engineers and chemists with an interest in the synthesis, characterization and utilization of nanoscale materials. We support this work with fundamental studies of phase behavior and transport in soft condensed matter systems and the kinetics of reactions used in materials synthesis. Much of our work involves a class of compressed gases called supercritical fluids (SCFs). SCFs can be viewed as a hybrid of liquid and gases that offer tunable solvent properties and unique advantages for the study and processing of nanoscale materials. Please browse through our site to learn more about the group, our research, and opportunities for technology transfer. Please feel free to contact us with questions and comments.

Contact Information:

Dept. of Polymer Science & Engineering

Room A616, Conte Research Center

University of Massachusetts

120 Governors Drive

Amherst, MA 01003

Phone: 413-545-2569

Fax: 413-545-0082

E-mail: watkins@polysci.umass.edu

Our current efforts are divided loosely into three broad areas, each of which involves a number of projects. First, we have developed fundamentally new approaches to the preparation of hierarchical materials, including mesoporous metal oxides and carbons, by the three dimensional replication of block copolymer templates in supercritical carbon dioxide. Second, we study phase behavior and dynamics in polymer systems dilated with SCFs to address fundamental issues including the effects of compressibility on polymer phase transitions and scaling behavior in highly concentrated systems and to aid in the development of novel processing strategies and new materials. Finally, we pioneered a new approach to metal and metal oxide depositions from supercritical fluids that is proving to be enabling for device applications.

3-D Replication of Macromolecular Templates for Hierarchical Device Structures

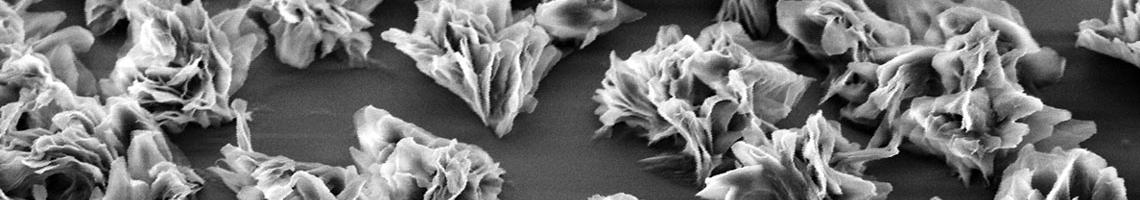

Ordered, nanostructured metal oxide and carbon films offer tremendous potential for applications in sensing and detection, catalysis, separations, photonics, magnetics and microelectronics. The optimization of these materials for practical use requires strict control over porosity, pore structure, matrix composition and, ultimately, the ability to control long range order and patterning at the device level. While complete specification of nanostructures is now fully accessible using the self and directed assembly of block copolymers, analogous control in other materials is not. We developed a new approach to mesoporous silicate, carbon and titanium dioxide films that involves the infusion and selective condensation of metal oxide precursors within one phase domain of highly ordered, preformed block copolymer templates using supercritical carbon dioxide as the reaction medium. The template is then removed to produce the mesoporous film. To date we have replicated ordered spherical and cylindrical morphologies to yield mesostructured films over 1 micron thick while maintaining all the structural details of the sacrificial copolymer template. Separation of the template formation and infusion steps is enabling as structure on both the local and device levels can be achieved wholly in the polymer template prior to infusion of the inorganic phase. For example, we have found that phase-segregated block copolymer films with cylindrical domains oriented normal to the substrate can be replicated to yield the corresponding silicate and titania mesostructures containing arrays of continuous, perpendicular channels with tunable pore sizes. We are now extending this work for the encapsulation of biomaterials and other active materials using biomimetic catalyst systems that promote silica condensation at mild conditions.

Specific projects in this area include:

Ultra low k and directly patterned silicate films for applications in microelectronics (Supported by NSF NIRT 0304159)

Synthesis of hierarchical silicates using biomimetic catalysts and encapsulation of biomaterials (Supported by AFOSR)

Hierarchical metal oxide films for next generation sensors (Supported by NSF CTS 0529034)

Nanochannel arrays in titania for applications in photovoltaics

Mesoporous carbons by block copolymer template replication

Phase Behavior, Structure and Dynamics of Concentrated Polymer/SCF Systems

The sorption of compressible fluids in polymer systems can be precisely controlled with pressure Therefore these systems provide an attractive opportunity to study behaviors in the concentrated regime. In blends and block copolymers (BCPs) that exhibit lower critical phase transitions, sorption of a few weight percent of a compressible fluid can induce phase separation at temperatures hundreds of degrees below those of the binary polymer system at ambient pressure. This behavior, which is markedly different from that expected from liquid solvents, is attributed to disparate increases in the compressibility of the mixture components upon the sorption of fluid. In contrast to LCST-type systems, the effect of CO2 sorption on upper critical solution - type transitions such as the order-disorder transitions (ODTs) in block copolymers mimics that of liquid solvents and promotes miscibility. Here, we are interested in scaling of the ODT with solvent volume fraction in highly concentrated (>95%) BCPs. We are also examining the effects of solvent sorption on domain spacing in highly concentrated systems and find universal power law behavior for polystyrene-block poly(dimethylsiloxane) copolymers can be attained by accounting for swelling asymmetry due to selective solvent sorption.

Reactive Deposition of Metals and Metal Oxides from CO2 Solution

The demands of present and future microelectronic, optoelectronic, data storage and system-on-a-chip (SOC) device fabrication place stringent requirements on materials deposition schemes that to date have not been fully satisfied. These include conformal coverage of complex surfaces, complete filling of narrow (<100 nm) high aspect ratio structures, the capacity for mixed depositions of prescribed stoichiometry, reductions in the thermal budget during fabrication, and mitigation of the negative environmental impact of current processes. Supercritical fluid deposition (SFD), a new technique developed in out laboratories, can meet each of these objectives.

Deposition of metals within high aspect ratio features (supported by NSF GOALI and industry partners)

Conformal deposition of metal oxide films (supported by industry partners)