- Homopolymers Under Confinement

- Chain Configuration

- Chain Dynamics

- Nanorods

- Gels

- Polymer Mixtures

- Block Copolymers

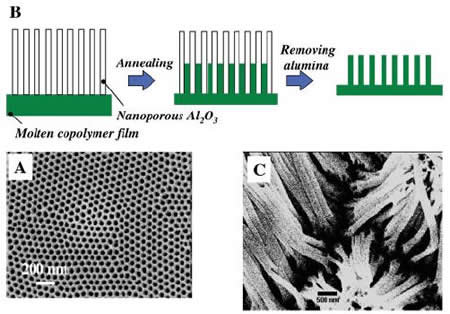

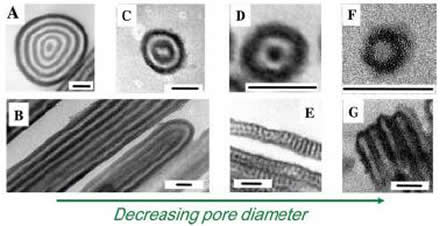

In the bulk, block copolymers microphase separate into nanoscopic morphologies including spheres, cylinders and lamellae depending on the volume fraction of the components. The size of the domains is defined by the molecular weight of the copolymer and the strength of the segmental interactions between the blocks. If a block copolymer thin film is confined between two solid interfaces, the copolymer chains will either stretch or compress. The incommensurability between the copolymer period and the interface separation distances will alter the fundamental repeat period. When the block copolymers are forced into cylindrical nanopores, where the diameter of the nanopores are several repeat periods of the copolymer morphology, both commensurability and imposed curvature influence the morphology. We have used porous alumina membrane to provide the cylindrical confinement. Confinement effects are found to distort the natural packing of the microdomains and cause an apparent deviation of the repeat period from the bulk values. Under severe confinement, where the pore diameters are comparable to the equilibrium period of the copolymer, morphologies different than those observed in the bulk are seen. Stacked torus-type structures, helical cylinders and helical strings of spherical structures were seen for lamellar, cylindrical, and spherical copolymers, respectively.

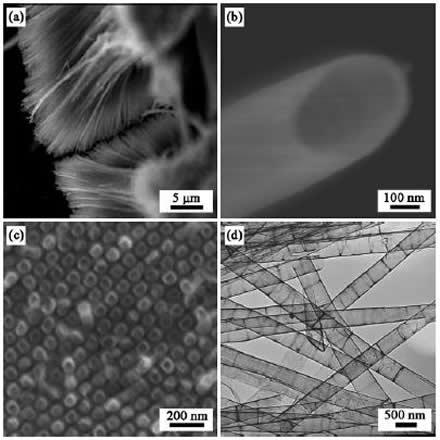

Porous alumina membranes were also used to generate amorphous carbon nanotubes(CNTs). Polyacrylonitrile(PAN) and polystyrene-block-polyacrylonitrile (PS-b-PAN) were used as carbon precursors. Uniformly aligned amorphous carbon nanotubes were synthesized by the wetting and sequential pyrolysis. The thickness of the carbon nanotube walls can be controlled by either changing the concentration of the precursor solution or by using multiple wetting and pyrolysis steps. When diblock copolymers of PS-b-PAN were used, it was found that, nanopores were created within the nanotube wall after pyrolysis. The CNTs in this study were found to be amorphous from Raman spectroscopy and x-ray diffraction. However, the graphitization level of the CNTs is expected to increase by adjusting processing conditions, in particular the pyrolysis temperature. The CNTs can also be used as a shrouding to confine other materials, such as block copolymers. |

|

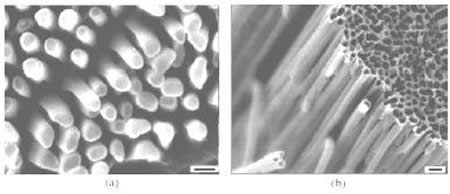

When the porous alumina membranes are wetted by polymer melts, two wetting regions (partial wetting and complete wetting) are observed. These regions are similar to the case of a flat solid substrate. In the partial wetting region, polymer melts are drawn into the nanopores via capillary force, forming polymeric nanorods. In the complete wetting region, polymer melts form precursor films and spread on the inner walls of nanopores in alumina membranes, forming polymeric nanotubes. We studied the wetting behavior of molten polystyrene, using nanoporous alumina membranes, by systematically changing the annealing temperature and polymer molecular weight. A transition from the partial to complete wetting was observed when the annealing temperature was raised above a critical temperature Tw, which is related to the increase of spreading coefficient S with increasing temperature. The difference in wetting rate between two wetting regions was also used to fractionate polystyrene with different molecular weight.

|